Characteristic of Cut Knurlilng Tool

Turning external diameter cut knurling tool can adjust the cutting angle, can protect the accuracy of the machine tool, for small machine tools, rigid requirements are low.

Applicable types of machine tools: CNC lathe, automatic lathe, multi-axis lathe, Swiss automatic lathe, Lathe-milling machine tools.

Double Wheel Cut Knurling Tool

可加工网纹,刀具可根据加工工件直径的大小对滚轮的切削角度进行调整,同时具有中心高调节功能,可以确保双轮同时接触工件,避免乱花现象。

The Tool can process overlapping curve.The cuuting angle can be adjusted according to the workpiece diamater.And had center adjustment function,it can ensure the wheels work at the same time.

Knurling Type

|

Knurling Type |

Cut Knurling Wheel | Feed Type | |

|

RGE30° | AA+AA | F← |

|

|

RGE45° | BL15°+BR15° | F← |

|

RGE60° | BL30°+BR30° | F← |

Imported Cut Wheel

| AA | BL15° | BR15° | BL30° | BR30° |

|

|

|

|

|

Product Data

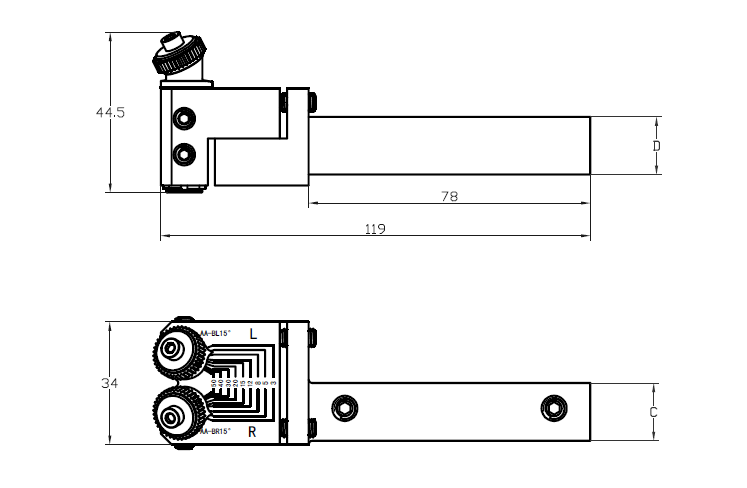

CH2145 drawing

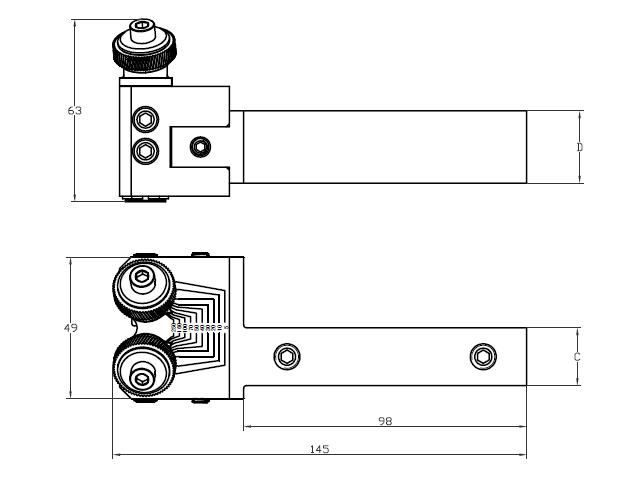

CH2215 drawing

| Model | Direction | Process Range | Wheel Size | Tool Shank Size |

Spare Part |

||

| C | D | ||||||

| CH2145R14 | R 正 | φ3-50 | φ14.5×3×5 | 14 | 16 | EAT14.53 |

|

| CH2145L14 | L 反 | ||||||

| CH2145R16 | R 正 | 16 | |||||

| CH2145L16 | L 反 | ||||||

| CH2215R20 |

R+L 正反可调 |

φ5-250 | φ21.5×5×8 | 20 | 25 | EAT21.55 | |

| CH2215R25 | 25 | ||||||

Cut Knurling Tool Use Method

1.Install tool into tool holder and adjust tool center height to ensure center position of workpiece.

2.Adjust the wheel to the outer diameter of the workpiece and adjust the width of the two wheels to close the workpiece.

3.Start to work,fast cut 1/2 of the teeth pitch and width is about 1/3 of wheel

4.Start Z axial feed when the knuling pattern is finished.

5.If the tooth type is faulty, adjust the axial adjustment of the cutter holder.

6.Use larger cutting fluid or lubricant to remove the iron scraps